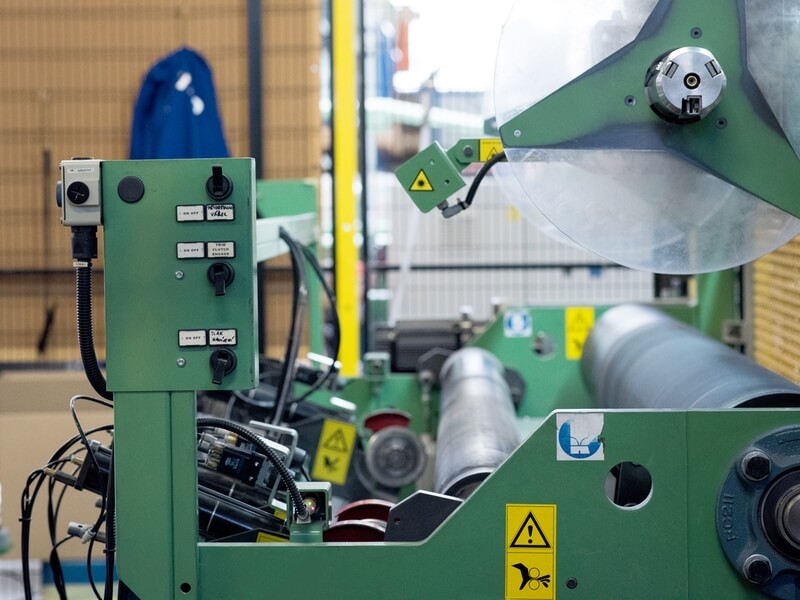

In 2001, we have started the production of endless abrasive belts. At the beginning of 2003, replacement of machinery was carried out and at present, we are able to bond both wide and narrow belts. They are produced on modern semi-automatic high precision machines ensuring high quality of joints.

What is the production process?

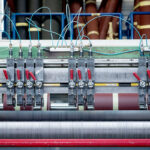

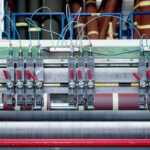

Wide belts are manufactured on a set of BIKO machines. BTFW LS automatic scissors, and BIKO CSM-05 modern semi-automatic grinder. It is a continuous machine where a joint is prepared and adhesive is applied on both belt ends in a single passage, and they are bonded and pressed together in the production line. Joints are aligned in the production line, which ensures stable quality of joints.

Also segments for the production of segment belts can be prepared on the grinder that are then put together and pressed on a press for segment belts.

Parameters

| Belt width: | 300 – 1600 mm, segment 1500 – 3500 mm |

Belt length: | 750 – 8000 mm |

Joint type: | E07, E27, E13, E14 |

| Materials: | paper D- G , combination, cloth F, J, X, Y |

Capacity: | 600 pcs per shift |

Two lines are used for the production of narrow belts. CSM-02 machine is used for wood grinding belts and long belts and CSM-07 is used for taped belts.

Belts are cuts to required length in BTH-AF automatic scissors. PNP20 hydraulic press is used for pressing of joints. Bonded belts are cut into required length on SBS300, ABS-450 cutters.

Parameters

| CSM-02 | |

Belt width: | 150 – 600mm |

Belt length: | > 500 mm |

| Joint type: | E07, E27, E13, E14 |

Materials: | paper A – G, polyester, cloth F, J, X, Y |

Capacity: | 800 belts 300mm per shift |

CSM-05 | |

| Belt width: | 150 – 600mm |

Belt length: | > 250 mm |

Joint type: | E07, E27 |

Materials: | polyester, SCM, cloth F, J, X, Y |

Capacity: | 600 belts 300mm per shift |

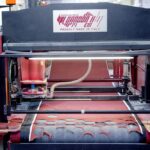

Circular cuts and sheets are cut on CNC hydraulic and electromechanical presses with a movable head. We produce all standard dimensions of cuts from all available abrasive materials.

Our state-of-the-art machine is BIKO EDP which also provides automatic counting and stacking of the cuts.

Parameters

Chiesa F1 | |

System: | electromechanical |

| Cut dimensions: max. | 250 x 250 mm |

| Layers: | 1 – 6 |

Materials: | paper, cloth, polyester |

| Capacity: | 15,000 cuts / layer and shift |

| BIKO EDP | |

System: | electromechanical, automatic stacking |

| Cut dimensions: | max. 450 x 450 mm |

| Layers: | 1 – 6 |

Materials: | paper, cloth, polyester |

| Capacity: | 15,000 cuts / layer and shift |

SYSCO ABR | |

System: | hydraulic, automatic stacking |

| Cut dimensions max.: | max. 500 x 500 mm |

| Layers: | 1 – 3 |

Materials: | paper, cloth, polyester |

| Capacity: | 10,000 cuts / layer and shift |

Lacom laminating line is used for lamination of a “velco fastener” to abrasive materials. We use high quality PUR reactive hot melt adhesives that ensure perfect adhesion of the fabric to the abrasive material.

The step that follows immediately after lamination is material printing, carried out on a printing machine that prints data on grain size, safety instructions or customer logos.

Parameters

Lacom | |

Adhesive: | hot melt reactive PUR |

Width: | 300 – 1800mm |

Abrasive materials: | paper A – G , polyester, non-woven textile, cloth F, J, X, Y |

| Hook-and-loop fasteners: | polyamide 50 – 200 g/m2 |

Capacity: | 2000 m per shift |

Printer | |

Ink: | water-soluble |

Color: | 1 arbitrary |

Width: | 1600 mm |

Materials: | paper, cloth, polyester, hook-and-loop fastener |

We produce locking-type discs on a simple manual press. In one step, the cut-out and the sleeve are centred, the glue is applied and the pressing is done. We use high quality PUR reactive hot melt adhesives that guarantee high bonding strength.

Parameters

Adhesive: | hot melt reactive PUR |

Locking: | bolt |

Diameters: | 38,50,75 mm |

Materials: | Y cloth, fibre |

Capacity: | 2000 pcs per shift |